Project Description

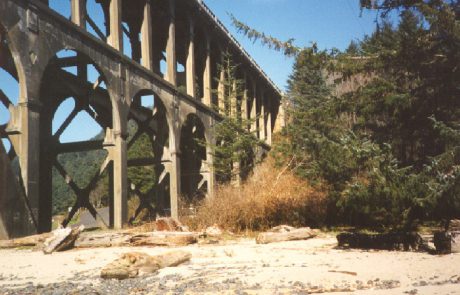

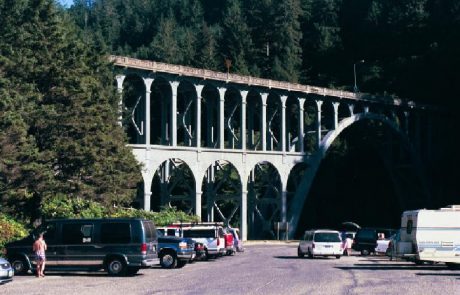

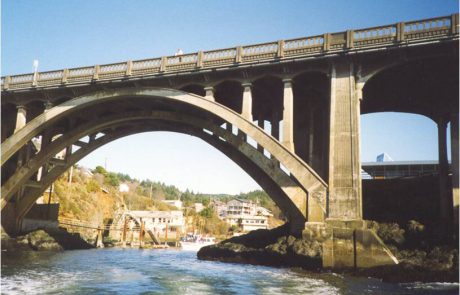

CAPE CREEK BRIDGE REHABILITATION PROJECT (1990-91)

The Cape Creek Bridge Rehabilitation project was the largest renovation and cathodic protection project ever undertaken anywhere in the world in 1990. We at GWC were selected to work with ODOT in developing and expanding the knowledge and procedures as they pertained to impressed current cathodic protection systems on steel reinforced concrete bridges. Many of the techniques and procedures developed back on the Cape Creek project are still the Oregon industry standard today. The Cape Creek project began in April of 1990 and ran through December of 1991. There were115,000 square feet of zinc applied, and 7,780 square feet of concrete restored.

The Cape Creek Bridge Rehabilitation project was the largest renovation and cathodic protection project ever undertaken anywhere in the world in 1990. We at GWC were selected to work with ODOT in developing and expanding the knowledge and procedures as they pertained to impressed current cathodic protection systems on steel reinforced concrete bridges. Many of the techniques and procedures developed back on the Cape Creek project are still the Oregon industry standard today. The Cape Creek project began in April of 1990 and ran through December of 1991. There were115,000 square feet of zinc applied, and 7,780 square feet of concrete restored.

As of an inspection survey in 2006, approximately 80% of the zinc anode was still sound and the CP system functioning.

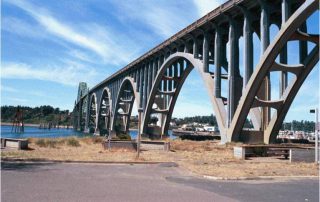

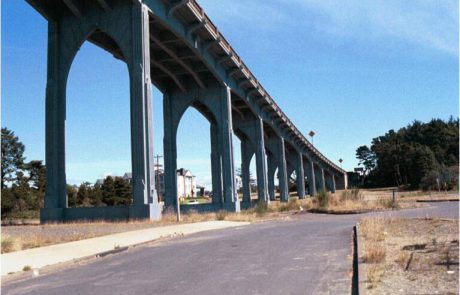

YAQUINA BAY BRIDGE ARCH SPANS (1992-94)

The Yaquina Bay Bridge Arch Span projectr was again the largest Restoration and Cathodic Protection project in the world during it’s time of renovation. The Yaquina Bay Bridge was comprised of 195,000 square feet of concrete surface to apply zinc anode on, and 21,250 square feet of concrete restoration. The Yaquina Bay project was began in August of 1992 and was completed in 1994. GWC was again selected as one of the key players in the cathodic protection process on this project. A recent inspection survey on the Yaquina Bay Bridge found that approximately 60% to 70% of the zinc anode was still sound and functioning.

Over the past twenty two years GWC has successfully completed, or been a key player in completing, over 730,000 square feet of concrete surface and cathodic protection of steel reinforced concrete structures.

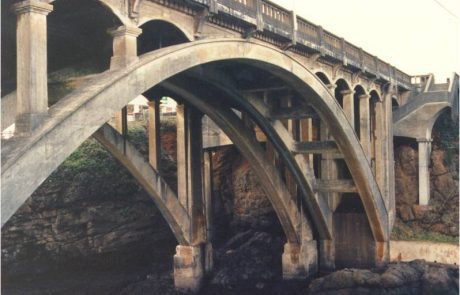

DEPOE BAY BRIDGE (1993-96)

This bridge was originally constructed at half the existing road. This provided a unique set of circumstances to enclose two double-arches that were not aligned with each other and to perform repair operations on what was essentially two separate structures that used construction methods decades apart. This project included 70,000 square feet of cathodic protection. As it is located in the heart of the little tourist town of Depoe Bay, Oregon, performing the work with the minimum impact to pedestrian or motoring traffic was essential.

YAQUINA BAY BRIDGE SOUTH APPROACH SPANS (1996-97)

This was the third phase of the cathodic protection system installed on the bridge in Newport. It included 65,140 square feet of cathodic protection.

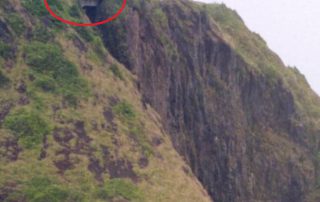

CAPE PERPETUA VIADUCT (1997)

This is actually half a bridge that is built into the hillside. It also required a platform and enclosure hanging over a cliff. Three different types of cathodic protection were installed on this project so that ODOT could study the effectiveness and practicality of new technologies in this field. Impressed current c.p. with metalized zinc, galvanic c.p. with metalized zinc-aluminum-indium, and zinc hydrogel, a new adhesive system from 3M, were installed to provide 1,839 square feet of cathodic protection.