The Basics

Cathodic protection is basically an electrical process which follows the long- accepted anode-cathode processes utilized on ships and pipe-lines for years. The process, as applied to concrete bridges, utilizes the existing steel rebar as the negative and the zinc coating as the positive. All installation work is completed in an enclosure designed to withstand wind loads of 90 mph, with a heating, dehymidifying, and negative air system capable of maintaining a surface temperature on the concrete structure of at least 70 degrees Fahrenheit.

In order for an impressed current cathodic protection system to work, many phases of repair and preliminary work are performed on the structure prior to the installation of the 99.9% pure zinc coating. Damaged or delaminated concrete is located, removed, and replaced. Any metallic objects within 1/2″ of the surface must be located and removed over the entire surface area of the structure to prevent the zinc coating from short-circuiting with the rebar. Any damaged or deteriorated rebar are replaced. The rebar in the structure is tested for electrical continuity, and any deficient areas are electrically connected, to ensure that all rebar is sufficiently connected to carry the cathodic protection current throughout the structure. An in-depth corrosion potential survey is performed over the entire structure to determine the areas of greatest corrosion activity, or “hot spots”. Reference Electrodes are then installed in the concrete along-side the rebar in those “hot spots”. Those reference electrodes are later wired up to a remote monitoring system that will allow the Owner of the structure to remotely monitor the corrosion potential and ensure that adequate power is being impressed into the system to prevent future corrosion. Anode terminal plates are installed counter-sunk and flush mounted on the concrete surface. These provide an attachment point for the wiring, which will supply the impressed electrical current, and distribute that current to the zinc. Only after all preliminary phases are performed and inspected is the 15-20 mils of 99.9% pure zinc coating applied to the concrete surface. Finally, conduit and wires are run to provide the D.C. electrical current for the system.

Also see this video from Modern Marvels that gives an overview of cathodic protection and how it is used to protect the bridges along the Pacific Coast Highway.

Yaquina North Dac 85 1984

Pile Jackets Alaska 1998

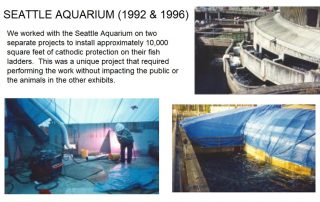

Seattle Aquarium 1992 & 1996

Alaska Floating Bumper 2000

Passive Puck Anodes 1996

Anode Sled & Ref Electrode 2020

Freeze Resistant Water Tower 1986

Anode Sled